There are various types of compacting machines that can be used for soil compaction. These machines have varying operating ranges and material properties, and they are most economical when used for a specific project. Choosing the right one can help you complete the job more efficiently and economically. So, find compaction machinery for sale on Truck & Trailer right now.

Most of the field operations in modern agriculture are carried out using heavy equipment. However, the effects of these machines on the soil can cause soil to become unstable. This condition is considered a serious environmental issue that can have detrimental effects on the environment and the development of the world's agriculture. Soil compaction can also lead to the reduction of soil structure and plant growth.

In this article, we will go over the different types of compaction equipment and how to select the correct one for your needs.

Photo by Glen Carrie on Unsplash

Photo by Glen Carrie on Unsplash

Different Types of Soil Compaction Equipment:

There are two types of soil compaction equipment: light soil and heavy soil.

1. Light soil compaction equipment

Various types of compacting equipment, such as rammers, vibratory tampers, and vibratory plate compactors, are commonly used in constrained areas to compact materials. They are mainly used for compacting small areas of soil. Here are some light equipment options for soil compactions.

Vibratory tampers

These vibratory tools are ideal for use in smaller areas and confined spaces. They can be used to compact different types of soils and are usually manually guided. They weigh around 50 to 100kg.

For use with packing soil, the vibration tamper's guide handle is elastically attached to the device's head. The pivot point of this mechanism is positioned above the head's imaginary parallel, which extends from the handle's grip area to the longitudinal axis. The handle's mass distribution can vary depending on its pivot point.

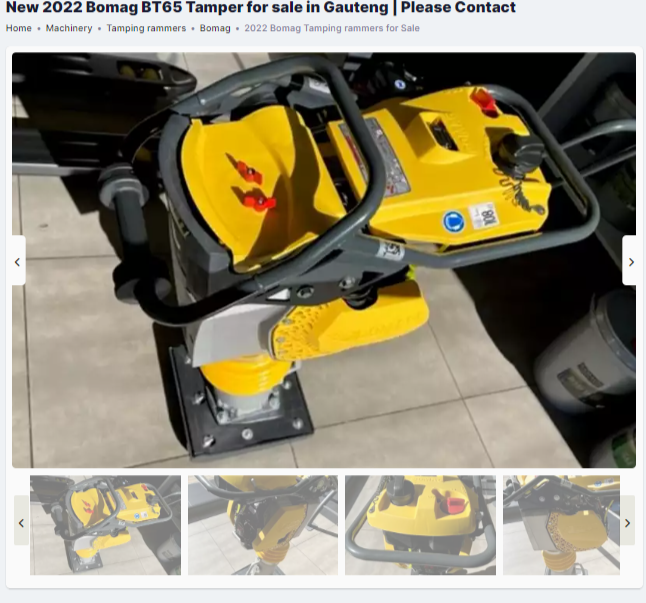

Rammers

Rammers can compact various types of soil in deep and medium layers, including trenches, foundations, backfills, and more. It's ideal for work in confined areas, where high density is required. The top layer of the container should be at least 150mm thick.

The base size of rammers varies from 15 x 15 to 20 x 20cm². Their weight is usually around 30kg to 10 tons. Additionally, they can also fall freely from a height of around 1 to 2 metres as they crush the rock underneath them.

Vibratory plate compactors

Compaction of various soil types using a vibratory plate compactor is commonly used in areas where it is not feasible or economical to use large equipment. Depending on the project's scope, different types of equipment will be used for the process. The most common type of compaction that is used for this type of work is for 4 to 8% fine soil removal. With the help of impact and vibrations, it can be done in a non-cohesive manner.

Vibratory plate compactors are also commonly used on coarse soil types, such as sand that has up to 8% fine particles. Compared to rammers, which compact the soil by producing an impact, a vibratory plate compactor uses vibrations to compact it.

Photo via Truck & Trailer Marketplace

2. Heavy soil compaction equipment

They are commonly used for compacting large areas with different types of soils. Heavy soil compaction equipment can reduce the amount of effort required to maintain the compact area.

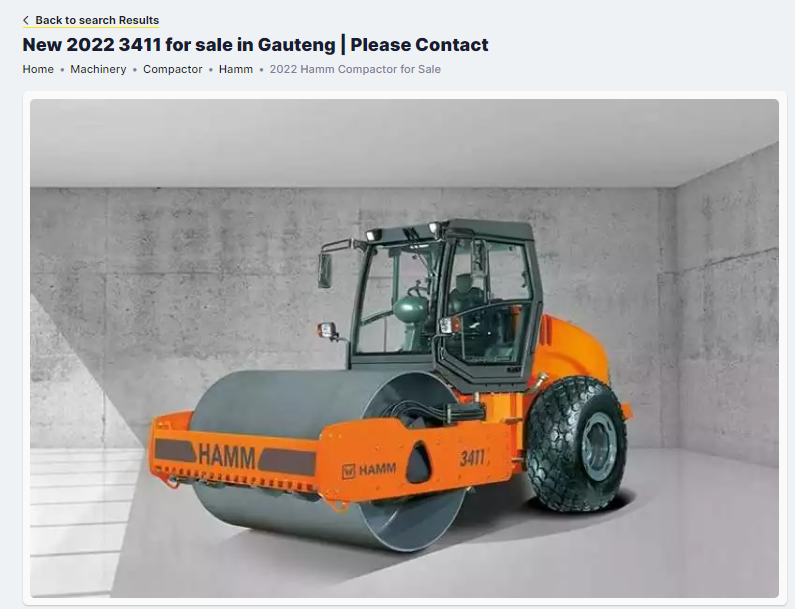

Smooth wheel rollers

These types of rollers are commonly used to compact the base course of roads and for the paving of airfields and highways. They are made of three different types of wheels: a front wheel, a rear wheel, and a drum-shaped one. Static compression is carried out through these wheels. These are commonly utilised in the construction of roads and airfields.

Although smooth wheel rollers can compress the soil and clay, their design allows them to compact the materials they pick up as well, such as crushed rocks and sand. They are commonly used to pave roads and highways, however, due to their lack of traction, it can be dangerous to drive them on wet surfaces.

Sheep foot rollers

The sheep foot roller is similar to smooth wheel rollers in that it has a smooth drum in front and a sheep's foot or a tamping roller in the rear. Unlike smooth wheel drums, these have tires on the rear.

This type of roller is commonly used to compact hard and silty clays and other fine-grained materials. It can also be utilised in various construction projects such as dams, railroad construction projects, pavements, and embankments.

The sheep foot roller has two types of equipment movement: vibratory and static. The former is used for the removal of fine-grained soil, while the latter is for the stabilisation of sand-gravel mixtures. This type of roller is most often used for the subgrade layers of railway and road projects.

Heavy pneumatic-tyre rollers

The four independently spaced tires are used on the rolling components, which can transport up to a total of fifty tonnes. They are ideal for handling finer silt and gravel and are typically towed.

The advantages of using heavy pneumatic-tyre rubber rollers over multi-tyre rubber rollers are their ability to compact deeper layers.

Photo via Truck & Trailer Marketplace

The benefits of soil compacting

- Compared to loose soil, compressed dirt tends to be more stable. This is beneficial for various types of equipment to move on, such as cranes and forklifts.

- With lifting devices, you can safely carry heavier loads on flat surfaces or stable ground. Soil compaction equipment can help you maximise the capacity of your lifting apparatus.

- When water flows through soil or dirt, it can affect equipment and slow down work progress. Compressed ground can help keep water away from a worksite.

When it comes to choosing the right equipment for your project, make sure to get in touch with the right individuals. At Truck & Trailer, you will find a wide range of soil compaction machines for sale. Visit our website now.